A world leader in fluid control systems, Bürkerts dedication to optimization of processes across multiple sectors made them ideal candidates for Gammasonics to partner with. The organizations pneumatic knowledge and dedication to mechanics has helped to minimise size and with affecting the operation of our EnviroRad System.

Here is an article recently published by Bürkert about their relationship about Gammasonics and our Enviro Rad system...

Gammasonics is an Australian company and research organisation recognised worldwide for its innovative research and design of radiation, protection, detection and measurement equipment.

Established in 1977, in its first decade of business the company developed the first nuclear medicine radiation detector, and also the first environmental radiation detectors to be installed in European airports to monitor the nuclear accident in Chernobyl. Following the Fukushima accident, Gammasonics contributed by providing radiation food contamination measurement equipment manufactured in Australia. The company now designs and manufactures a range of radiation-safety related technologies, one of which is widely used by hospitals to process radio-waste before disposing. One of the number of radioisotopes used in nuclear medicine for the treatment of hyperthyroid (overactive thyroid) is Iodine-131. I-131 has a long radioactive decay half-life of 8.02 days compared with the average radioisotopes injected into patients, which have a half-life of a few minutes or hours. The time that radioisotopes are active is referred to as ‘half-life’, which means that every eight days the isotope will be at half of the initial activity. As a result, environmental authorities across the world have created regulations that any iodine-131 isotope discharged into the environment should be withheld for a minimum of 90 days (approximately 11 times the half-life).

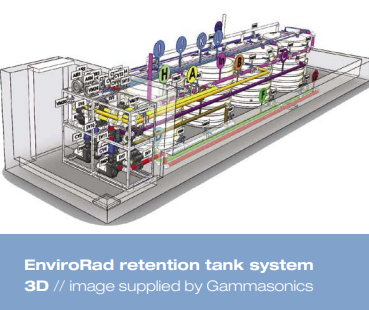

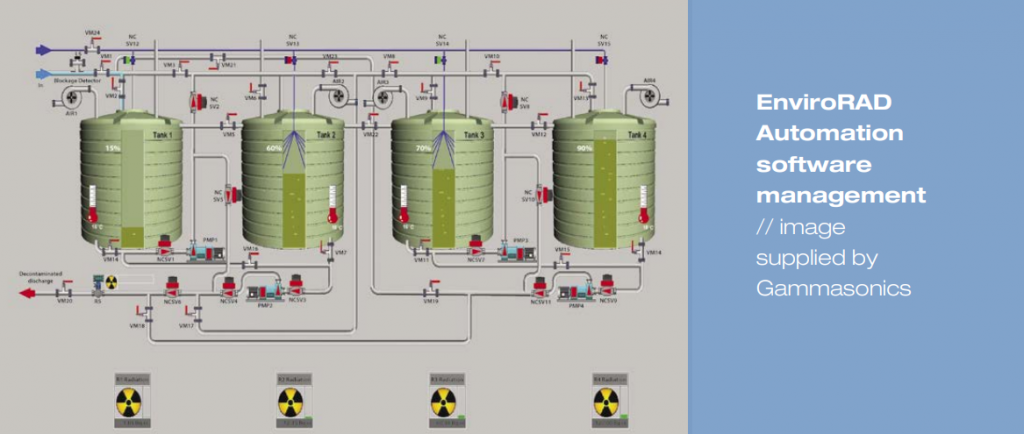

The technology utilised in the Gammasonics EnviroRad system cuts down the time of discharge to the environment to 33 days. It not only allows monitoring, but control of the process of dilution by adding oxygen into the effluent. The aeration accelerates aerobics, destroying solids, breaking down chemicals and diluting all the toxins that are introduced to the system. This minimises the ‘cocktail’ of toxins that occurred in previous retention tank systems that can include antibiotics, heavy metals, detergents and bacteria, as well as the radiation.

During treatment, patients need to be isolated in a special patient suite for 3-4 days to comply with the requirements for safe levels of radioactivity and to minimise exposure to members of the public. Radiological decay is one of the constant measurements that needs to be monitored, along with the biological decay constant. The majority of the iodine-131 isotope is depleted up to 60% in the first two days from the body of the patient. The EnviroRad system is directly connected to the patient’s suite to minimise exposure to operating staff. Gammasonics has also developed radiation detectors to measure the residuals of radioactivity in the patients before discharge from the hospital to minimise radioactive contamination and exposure to members of the public. “The main objective of EnviroRAD is to reduce the impact to the environment of products containing radiation, heavy metals, bacteria and antibiotics – all of which are very damaging to our environment,” said Professor Carl Munoz-Ferrada, Director of Medical and Scientific Research at Gammasonics. “Fertilisers, human waste, nitrates, and phosphates from sewage over-stimulate the growth of aquatic plants and algae,” he added. “We are causing mutation to flora and fauna by adding pharmaceuticals, chemotherapy drugs, antibiotics, and residual radiation to our waterways. “EnviroRad reduces the damage by limiting the radionuclide discharge from hospitals and facilities utilising Iodine-131 and other isotopes, thereby creating almost clear water.”

How It Works

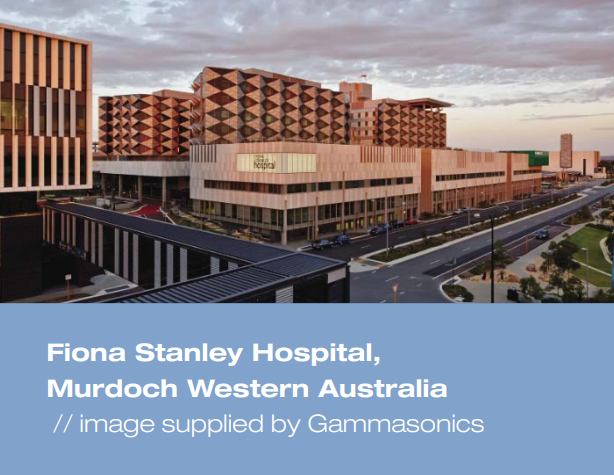

Starting with the first project for St Vincent’s Hospital in Sydney in 2001, today the EnviroRAD system has become the standard worldwide for hospitals aiming to achieve a completely safe environment, including the flagship hospital in Western Australian, Fiona Stanley Hospital in Murdoch. The kingdom of Saudi Arabia has been one of our greatest supporters, with our partners Abdullah Fouad, in the Middle East. Presently installations of the EnviroRad with Burket components are found in hospitals such as the National Guard Hospital, King Khalid & IMC, just to mention a few. The system automatically delays, decays and dilutes the discharge of radioactive substances into the waterways through monitoring and controlling the radioactive emissions from the waste until the substance reaches the activity level permitted by regulatory authorities. “The key element in the EnviroRAD process is the injection of air (containing 21% oxygen), which assists in the homogenisation and pasteurisation of the waste: killing bacteria that would otherwise build up when utilising the traditional method of storing the waste in a septic tank until the radioactivity has decayed below the regulatory level,” said Professor Ferrada.

How Bürkert helped

While Gammasonics has detailed expertise in the research and engineering associated with radiation technology and its maintenance, they relied on Bürkert to build the required control and automation panels for the EnviroRAD system. The company therefore worked with Bürkert to provide the technology, experience and expertise to build the control and pneumatic panels. Bürkert supplied control valves for this specialised application, and was able to offer a complete package for the field and control components, partnering with Gammasonics to bring it all together. “Bürkert supply the components to be utilised in the hydraulic and pneumatic systems that are central to the process functionality,” said Professor Ferrada. “They have given us technical support in the area of hydraulics and pneumatics, thus reinforcing the components they supply, which have simplified our system.”

The Technology

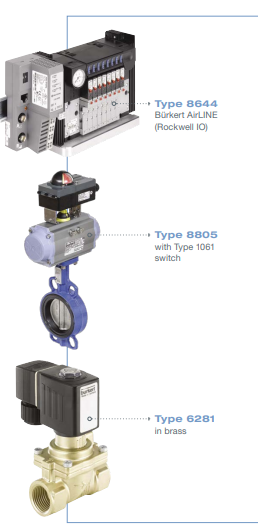

Bürkert supplied all the field sensing and actuation components, with the hardware being fully compatible with the Rockwell Point I/O control system. This included the AirLINE Type 8644 Remote Process Actuation Control System, which integrates high performance solenoid pilot valves, remote electronic I/O and fieldbus communication into a process actuation and control system that is compact and flexible. Its modular design allowed it to be customised for the needs of the EnviroRAD application, with direct integration into the Rockwell control system.

For aggressive media control, the actuation system used Bürkert’s Type 8805 quarter turn control valves complete with pneumatic rotary actuators, complimented with Type 1061 limit switches to provide position feedback.

For fluid control, the Type 6281 servo-assisted diaphragm valve was chosen, for which various diaphragm material combinations and methods of operation are available depending on the application, along with housings in brass or stainless steel satisfying the NEMA 4X standard.

“One of the problems previously encountered in building the EnviroRAD system has been the space restrictions we often encounter when installing large systems,” said Professor Ferrada. “By introducing pneumatic control into the system, Bürkert has enabled us to make it more compact.

“They have also increased our knowledge in the area of hydraulics and pneumatics, and provided the technical support we needed in relation to the control technology that has simplified the system.”

A Long-Standing

Partnership

Today, Bürkert and Gammasonics share a very long and successful history of working together.

“Over the years Bürkert has demonstrated the necessary expertise to provide solutions to any problem that has arisen,” said Professor Ferrada. “They communicate with our engineers regularly, stay educated on what we do, and keep informed about our upcoming projects. It has been proven more than once that Bürkert are an invaluable partner and ally to Gammasonics by advising and providing the right equipment for our projects”.

We learn from you every day

Including when we think outside the box

When it comes to dealing with liquids and gases, Bürkert is a sought-after partner all over the world. Why? Probably because we have been learning for, and from, our customers for more than 70 years. This enables us to always think that crucial step ahead – or even sideways.

We make ideas flow.

Bürkert Fluid Control Systems

Unit 8, 15 Columbia Way

Baulkham Hills NSW 2153

Australia

Phone 1300 888 686

Fax 1300 888 076

sales.au@burkert.com

www.burkert.com.au